The Haybuster PTO Tub Grinder line is made up of three sizes of grinders plus the option of an electric motor.

The Haybuster Model H-1000 tub grinder is the most economical grinder available. Designed for the small rancher who still needs to get the hay ground. Fifty to 100 head cattle ranchers have learned to appreciate the ability and price of the H-1000. Of course, to make the H-1000 affordable for the smaller rancher, it’s limited on certain features compared to other Haybuster models. The limited features include no tub tilt and a lighter-duty hammermill. This hammermill only requires an 80 hp PTO tractor and ideally a 125 hp tractor for its maximum efficiency. If your herd size and tractor size fit these criteria, this may be the tub grinder for you.

Features

18” Wide by 20’ Long Hydraulic Folding Conveyor

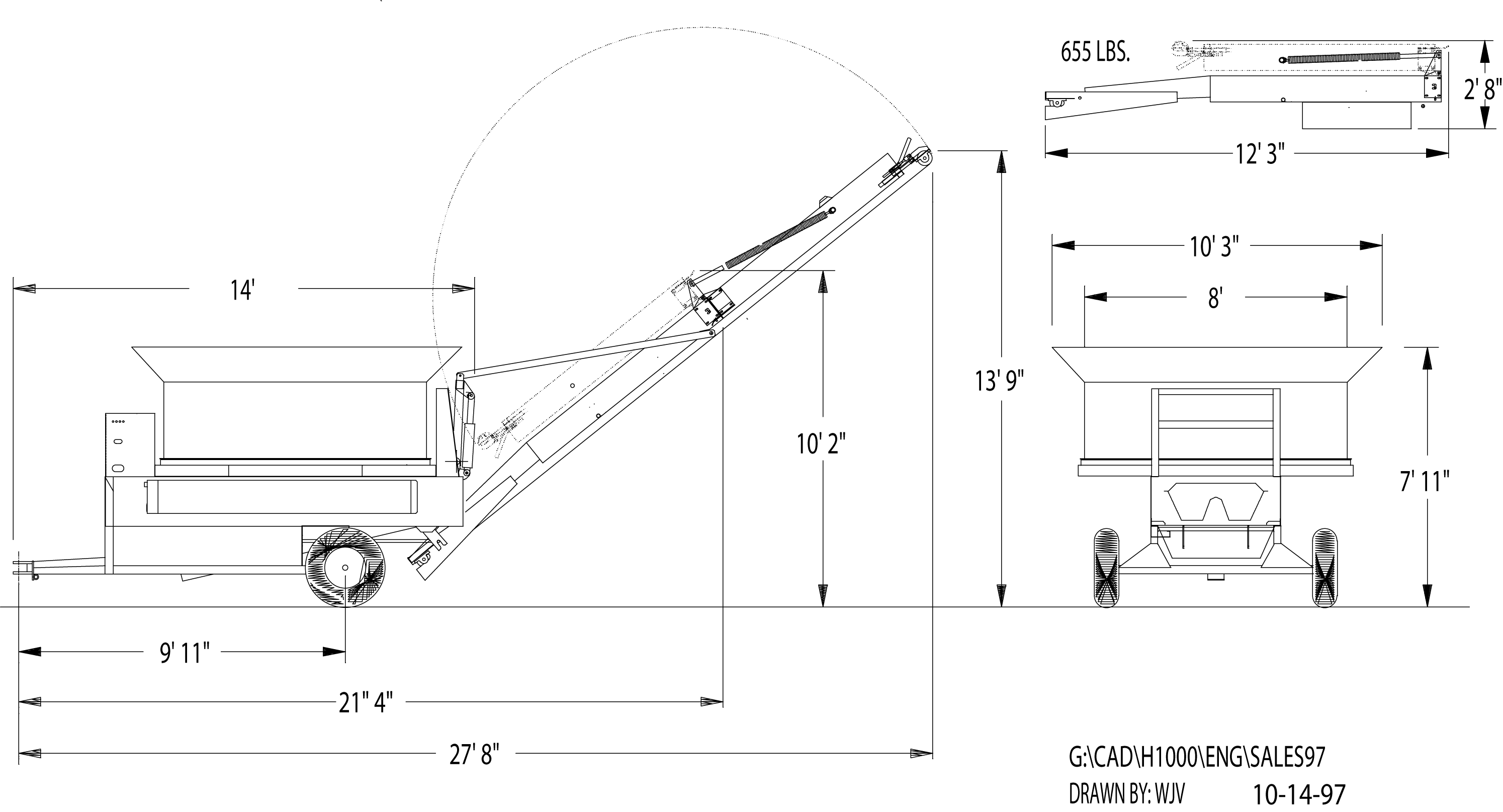

The model H-1000 tub grinder is now equipped with a hydraulic folding conveyor. The 20’ long x 18” wide conveyor allows you to stack ground material up to 13’9” high at a 40 degree angle.

Big Bite Hammermill

The hammermill is constructed of 3/16” thick x 15.75” diameter plates with 15/16” case hardened rods that hold 64-3/8” hammers. These hammers have 4 hardened edges that can be rotated and flipped to get many hours of grinding.

Eight Belt Drive System

The 8-groove belt drive system is dependable. It supplies the power from the PTO of the tractor to the hammermill. This drive system turns the mill at approximately 2 x PTO speed. This mill speed provides for smooth feeding and delivers high capacity grinding performance.

Find a Haybuster Dealer

Standard Features

- The Model H-1000 is now equipped with an 18” wide by 20’ long hydraulic folding conveyor. The conveyor allows you to stack ground material up to 13’ 9” high.

- The hammermill is constructed of 3/16” thick x 15 ¾” diameter plates with 15/16” case hardened rods that hold 64-3/8” hammers. These hammers can be rotated and flipped for many hours of grinding.

- The 8-groove belt system delivers sufficient power from the PTO to the hammermill. The system has a fixed belt tension to accommodate, stretch, and wear without having to monitor belt tension. This drive system turns the mill at approximately 2 x PTO speed. This mill speed provides for smooth feeding and delivers high capacity grinding performance.

- High-capacity grain grinding is another important operation that the H-1000 can also accomplish. By placing the optional grain-grinding hopper over the hammermill opening and changing screens, the H-1000 becomes a high capacity grain grinder for grinding and/or cracking feed grains.

- The H-1000 tub is driven by a hydraulic motor which drives a heavy-duty roller chain. The sprocket on the tub is a continuous sprocket that provides a positive and smooth transmission of power to the tub.

- The tub rotation is controlled by an electronic governor that stabilizes engine load by adjusting the tub speed based on rotor speed. It also controls tub direction and tub stop.

- The dual 9” high-capacity augers mounted in the belly pan discharge the ground product to the stacking conveyor. The belly pan provides a clean area to catch and discharge small product such as ground corn and barley.

- The hydraulic folding stacking conveyor is powered by a positive mechanical drive system.

- The H-1000 tub is 10’ 3” wide and 44 ½” deep and is constructed of a 10-gauge steel floor and a 14-gauge steel side wall. The H-1000 tub has the capacity to handle all types and sizes of bales.

Optional Features

PTO Shaft -1000 RPM

Tractor Half, 1-3/4 in, 20 Spline Shaft

Tractor Half, 1-3/8 in, 21 Spline Shaft

Tires

(Set of 2) 9.5 x 14 - 8 ply Implement Tires

(Set of 2) 31x10.5x15 - load rating “C” Highway Rated Tires

- Loose Hay Guide, Front

- Hopper for Grain Grinding

- Ear Corn Kit

Better diets for dairy cows - an article from the USDA - describes how finely ground grains/corn can offer a better diet for cows.

Closed Center Conversion Kit

This kit is required to operate the conveyor lift valve properly, with John Deere 60 and older series tractors.

Grinding Screens

1/8 in. (3.18 mm) Round Hole Screen Half*

3/16 in. (4.76 mm) Round Hole Screen Half**

1/4 in. (6.35 mm) Round Hole Screen Half

3/8 in. (9.52 mm) Round Hole Screen Half

1/2 in. (12.7 mm) Round Hole Screen Half

5/8 in. (15.88 mm) Round Hole Screen Half

3/4 in. (19.05 mm) Round Hole Screen Half

1 in. (25.4 mm) Round Hole Screen Half

1-1/2 in. (38.1 mm) Round Hole Screen Half

2 in. (50.8 mm) Round Hole Screen Half

3 in. (7.62 cm) Round Hole, Screen Half (standard)

4 in. (10.16 cm) Round Hole, Screen Half (standard)

Dummy (Open) Screen Half

*1/8 in. (3.18 mm) thick,

**3/16 in. (4.76 mm) thick, all other screens are 1/4 in. (6.35 mm) thick

Specifications

| WEIGHT | |

|---|---|

| Total | 6,830 lbs. (3,098 kg) |

| TRANSPORT DIMENSIONS | |

| Width | 10 ft. 3 in. (3.12 m) |

| Height | 10 ft. 2 in. (3.10 m) |

| Length | 20 ft. (6.10 m) |

| CHASSIS FEATURES | |

| Towing Arrangement | Clevis hitch |

| Bearings | Tapered roller |

| TUB FEATURES | |

| Loading Height | 8 ft. (2.44 m) |

| Tub Width at Flare | 10 ft. (3.05 m) |

| Depth | 44-1/2 in. (1.13 m) |

| Tub Inside dia at Base | 8 ft. (2.44 m) |

| Tub Wall Thickness | 12 gage (2.66 mm) |

| Tub Floor Thickness | 10 gage (3.42 mm) |

| Drive Mechanism | Full Sprocket around tub Electro/Hydraulic |

| Speed Control | Electronic Governor |

| HAMMERMILL | |

| Length | 44-1/2 in. (1.13 m) |

| Diameter, Hammers Extended | 26 in. (66 cm) |

| Feed Opening | 27 in. x 45 in. (68.58 cm x 114.3 cm) |

| Hammers | 3/8 in. (9.53 mm) Thick, A.B. Hardened Swing |

| Number of Hammers | 64 |

| Hammer Rods | 15/16 in. (23.81 mm) dia., Case Hardened |

| Cylinder Plates | 3/16 in. thick x 15-¾ in. dia. |

| Cylinder Shaft | 3 in. (7.62 cm), Stress Proof Steel |

| Drive End Bearing | 2-3/4 in.(6.99 cm), Pillow Block |

| Idle End Bearing | 2-7/16 in. (6.19 cm), Pillow Block |

| Screens | 1/8 in. (3.18 mm), 3/16 in. (4.76 mm), or 1/4 in. (6.35 mm) thick and various hole sizes from 1/8 in. (3.18 mm) to 4 in. (101.6 cm) |

| Screen Area | 2,400 sq. in. (15,483 sq. cm) |

| Drive | PTO through multiple V Belts |

| BELLY CONVEYOR | |

| Type | Double Free Floating Augers |

| Auger Size | 9 in. (22.86 cm) x 96 in. (2.44 m) |

| Width | 33-¾ in. (85.73 cm) |

| Drive | Mechanical |

| DISCHARGE CONVEYOR | |

| Type | Rubber Belt with Cleats |

| Drive | Mechanical |

| Drive & Idler Roller Type | “Easy Clean” |

| Length | 20 ft. (6.1 m) |

| Width | 18 in. (45.72 cm) |

| Maximum Conveyor Lift Height | 13 ft. 9 in. (4.19 m) |

| Conveyor Lift | Hydraulic |

| Conveyor Lift Cylinder | 3" x 12" (7.62 cm x 30.48 cm) |

| Conveyor Fold | Hydraulic Folding Over Rear of Tub |

| OPERATOR CONTROLS | |

| Tub Rotation | 3 Position Hydraulic Valve for Clockwise, Stop, & Counter-Clockwise |

| Tub Speed | DuraTech Model RCB93 Electronic Governor Stabilizes Engine Load by Controlling Tub Rotation Speed |

| Conveyor Lift | 3-Position Hydraulic Valve for Raise, Hold, & Lower |

| REQUIREMENTS FOR OPERATION TRACTOR | |

| PTO Horsepower Required | 80 HP (59.7 kw) to 175 HP (130.5 kw) |

| Min. Tractor Hydraulic Output | 8 gpm at 1500 psi (30.3 lpm x 10,345 kPa) |

| Hydraulic Remote Controls | (1) Double-acting control valve with quick coupler outlets |

| Electrical | 12 VDC |

| GRINDER | |

| Hydraulic Reservoir | 12 gallon (45.4 liter) capacity |

| Oil Requirement | Mobil 423, Co-op Super HTB or Equivalent |

| SMV Sign | Standard equipment |

| Road Lights | Standard equipment |