Bales go in. Loose hay comes out.

Do it all with the 1150 Tub Grinder from Haybuster. With the optional grapple loader, you're able to do everything with one piece of equipment that you know won't fail you. Find solutions for:

- Grinding Hay: big round & square bales, loose hay

- Grinding Crop Residues: straw, stover, and other types

- Grinding Grain: corn, sorghum, and all cereal grains

- Commercial Grinding Applications

Features

Command Console with Optional Remote Control

A central command console is conveniently located and controls all the functions of the machine. An optional remote control is available to keep you out of the dust. It controls the tub rotation, conveyor lift, conveyor articulation, and engine stop. The electronic governor keeps the engine RPMs constant, resulting in increased efficiencies and constant load. Additionally, the 1150 with grapple loader offers duplicate controls in the 7000 series loader cab.

Rotary Self-Cleaning Screen

The enclosed engine compartment and rotary self-cleaning screen protects the engine from dirt and debris buildup. An enclosed engine also reduces the noise level. The 1150 with grapple loader gives you easy access to the engine with a 3-door entry on either side, plus a front door for access to the radiator.

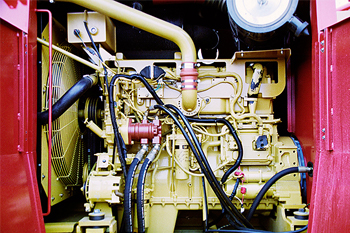

C15 Caterpillar Electronic Diesel Engine

Powered by a 540 HP (403 kw) C15 Caterpillar Electronic diesel engine with state-of-the-art electronic fuel injection system, fuel consumption is decreased and ground hay is produced at a rate that will make you money on every job. It’s strong enough to chew through those tough, wet bales, and it has all the features you’ve come to expect from Caterpillar, including reliability, cold weather starting, unsurpassed product support, and proven resale value.

KPTO Fluid Coupler

The KPTO fluid coupler transmits power with up to 98% efficiency and eliminates the mechanical clutch. It’s goof proof. It can engage or disengage at full engine RPM without damage and requires minimal maintenance.

50 Degree Oscillating Stacking Conveyor

The 30 in. wide x 26 ft. long stacking conveyor piles hay to over 18 feet in height. The conveyor can oscillate left to right up to 50 degrees, which means you can not only make the pile tall, you can make it wide as well.

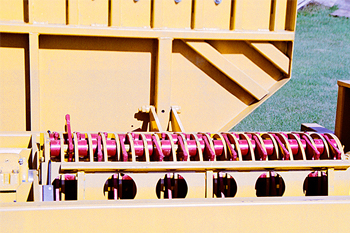

50” Big Bite Hammermill

The Big Bite hammermill is located at the rear of the tub frame, reducing the length of the belly conveyor, improving the belly conveyor service accessibility, and moving the dust away from the operator. The hammermill is also dynamically balanced to give you smoother operation, longer life, and less maintenance.

90 Degree Tub Tilt

The 11 ft. wide x 50 in. deep tilt tub opens a full 90 degrees for access to the hammermill and screens as well as for normal servicing.

11’ Tub with Tip in Tub Flares (Sides)

The 11 ft. wide x 50 in. deep tub has tip in tub flares (sides). The sides are folded in to narrow the transport width of the grinder.

Enclosed Engine Compartment with Easy Engine Access

The enclosed engine compartment and rotary self-cleaning screen protects the engine from dirt and debris buildup. An enclosed engine compartment also reduces the noise level. The 1150 with grapple loader also gives you easy access to the engine with a 3-door entry on either side, plus a front door to the radiator.

7000 Series Grapple Loader with Cab

The 7000 series cab rotates 270 degrees with the boom, includes all controls for operating the grinder along with electric/hydraulic joystick controls for grapple loader operation, has hydraulic outrigger legs for increased stability, and the cab can be raised up to 4 feet for unobstructed view and operator comfort.

29’ Grapple Loader

The 7000 series grapple loader features a 29’ fabricated boom, 8’ 4” wide reach grapple, replaceable grapple teeth, and an optional scale on the grapple can weigh individual bales.

Find a Haybuster Dealer

Standard Features

- 29-foot fabricated boom

- 8' 4" Wide reach grapple

- Replaceable grapple teeth

- Cab rotates 270 degrees with boom

- Cab raises 4 ft. for unobstructed view and operation comfort

- 540 HP (403 kw) Cat C15 Electronic Diesel Engine

- Enclosed engine compartment with self-cleaning air intake system

- Electric/hydraulic joystick controls

- Hydraulic outrigger legs for increased stabilization

- All controls for grinder are in the loader cab, as well as on the main control panel

- Weigh scale control panel easily monitored from the cab seat

Optional Features

- Optional scale on grapple weighs individual bales

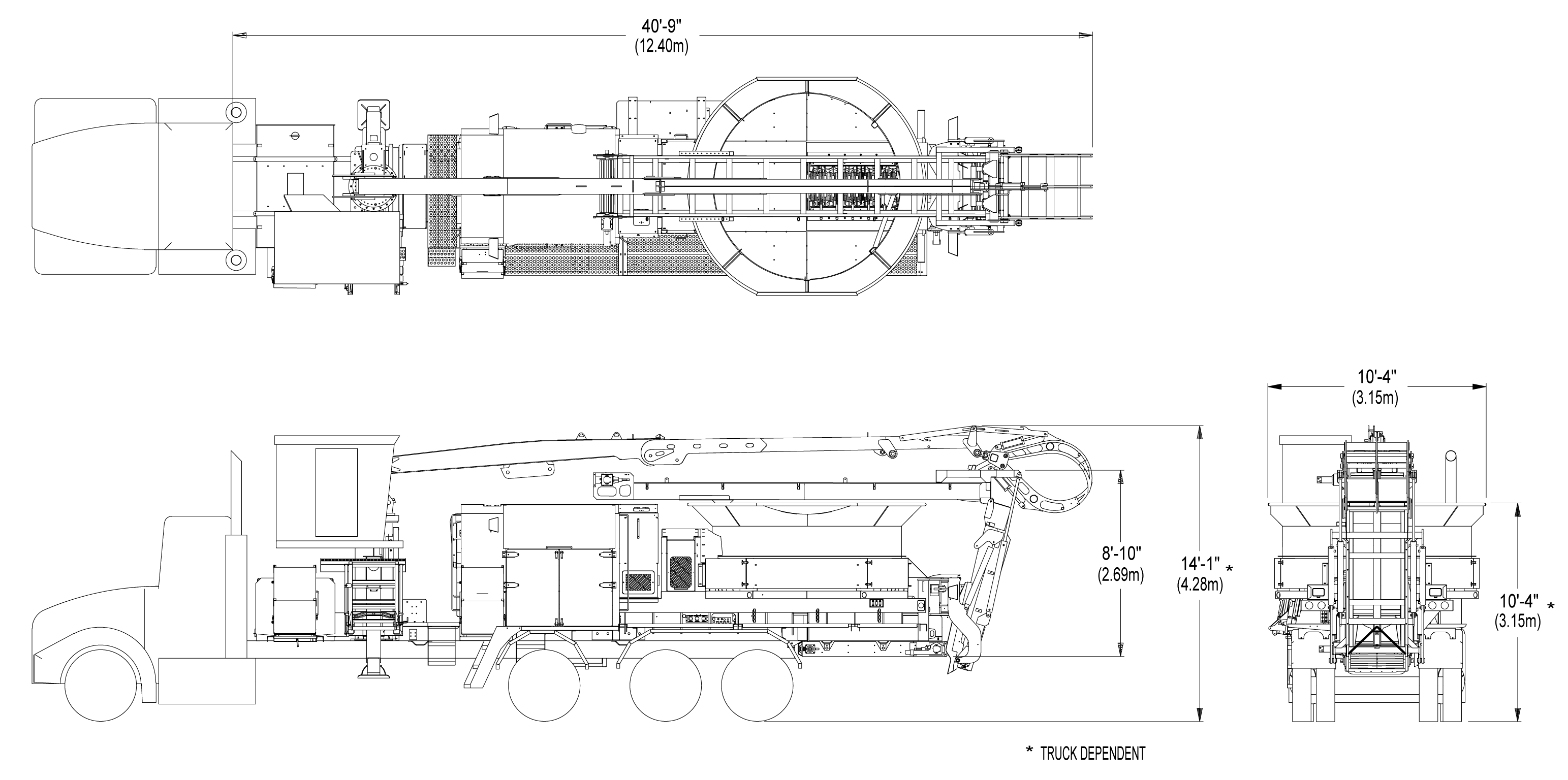

Specifications

| WEIGHT | |

|---|---|

| Total | 32,350 lbs. (14,704.5 kg) |

| TRANSPORT DIMENSIONS | |

| Width | 10 ft (3.048 m) |

| Height | 11 ft 6 in (3.51 m) |

| Length | 31 ft (9.448 m) |

| 7000 SERIES GRAPPLE LOADER | |

| Boom Length | 29 ft. (8.85 m) |

| Rotation | 270 degree |

| Wide Reach Grapple | 8' 4" (2.54 m) |

| ENGINE | |

| Manufacturer | CATERPILLAR |

| Model | C15 |

| Type | In-line, 6 cylinder, 4 -Stroke Diesel |

| Power Rating | 475 HP (354 kw) or 540 HP (403 kw) |

| Bore | 5.4 in (137 mm) |

| Stroke | 6.5 in (165 mm) |

| Displacement | 983 cu. in. (14.6 L) |

| Fuel System | Electronic Unit Injector |

| Aspiration | Turbocharged and air to air aftercooling |

| Compression Ratio | 16.25 : 1 |

| Rotation (from flywheel end) | Counter-clockwise |

| Engine Housing | A sealed enclosure with a rotary screen at the front that removes debris from the air prior to being drawn through the radiator. Air is directed around engine components to provide surface cooling and discourages dust buildup. Air exits out the bottom between the engine and right and left frame channels. 3 generous sized service access doors are provided on both the right and left sides. |

| Radiator | Staggered Core with 7 fins per inch |

| Cooling System | 9.2 gal. (34.8 L) |

| Lube Oil System (refill) | 10 gal (38 L) |

| Engine Air Induction | Clean air is drawn in front of radiator through an inline separator and dry type air filter with safety element. |

| Engine Block Heater | 120V / 2000 watt |

| FLUID COUPLING | |

| Manufacturer | TRANSFLUID |

| Model | Model KPTO-19 Fluid Coupling |

| Type | Drain Type Fluid Coupling |

| Charge Pump | Gear type |

| Cooler | Oil to air, thermostatic controlled electric fan |

| Features | Unloaded engine warm-up, smooth startup, shock and overload protection, absorbs vibrations, electric/hydraulic control valve |

| Maintenance | Easy access oil filter and drain plug |

| Fluid Capacity | 9.24 gal (35 L) |

| HYDRAULIC SYSTEM | |

| Cooler | Oil to Air, radiator mounted |

| Pump | Gear type, 2 section, output is 25 & 15 gpm @ 2100 psi., engine mounted |

| Control Valves | Electric/Hydraulic, 4 valves - 1) 4 spool, 2) single spool, and 1 proportioning |

| Reservoir Capacity | 50 gallon (171 liter) |

| Tub Tilt | 3 in x 30 in (7.62 x 76.2 cm) Hydraulic Cylinder |

| Conveyor Lift | 2) 3 in x 36 in ( 7.62 x 91.44 cm) Hydraulic Cylinders |

| Conveyor Fold | 2) 3 in x 30 in (7.62 x 76.2 cm) Hydraulic Cylinder |

| Conveyor Articulation | 2) 2 in x 8 in (5.08 x 20.3 cm) |

| CHASSIS FEATURES | |

| Fire Suppression | 2) 20 lbs (9.09 kg) Fire Extinguishers, front mounted on the right and left side of the main frame |

| Fuel Capacity | Truck Dependent |

| Lights | Clearance, Directional, and Brake |

| Towing Arrangement | Truck Mounted |

| Axle | Truck dependent |

| Brakes | Truck dependent |

| Tires | Truck dependent |

| HAMMERMILL | |

| Length | 50" (127 cm) |

| Diameter, Hammers Extended | 26" (66.04 cm) |

| Feed Opening | 25 in x 52 in (63.5 cm x 133 cm) |

| Mill Feeding | Mill Grate |

| Hammers | 1/2” (1.27 cm) AR-Hardened Steel , Swing |

| Number of Hammers | 88 |

| Hammer Rods | 1-1/4 in (31.75 mm) dia., Case Hardened |

| Mill Plates | 1/2" (1.27 cm) thick X 16" (40.64 cm) dia. |

| Mill Shaft | 4-1/2 in (114.3 mm), Stress Proof Steel |

| Bearings | 4 in (101.6 mm), Pillow Block Bearings |

| Drive | Direct from Fluid Coupling |

| Screens | 1/8 in (3.18 mm), 3/16 in (4.76 mm), or 1/4 in (6.35 mm) thick and various hole sizes from 1/8 in (3.18 mm) to 8 in (203.2 mm) |

| Screen Area | 2,781 sq. in. (7,063.75 sq. cm.) |

| TUB FEATURES | |

| Loading Height | 9 ft 6 in (2.89 m) |

| Tub Width | 11 ft (3.35 m) |

| Depth | 50 in. (127 cm) |

| Tub Diameter at Base | 9 ft (2.74 m) |

| Tub Wall Thickness | 12 gage (2.66 mm) |

| Tub Floor Thickness | 1/4 in (6.35 mm) |

| Drive Mechanism | Electro/Hydraulic |

| Speed control | Electronic Governor |

| Service Access | Tub opens to 90 degrees to the right side |

| BELLY CONVEYOR | |

| Type | Rubber Belt with 3/4 in (19.05 mm) cleats |

| Width | 36 in (91.4 cm) |

| Drive | Hydraulic |

| Drive & Idler Rollers Type | “Easy Clean” |

| STACKING CONVEYOR | |

| Type | Rubber Belt with 1-1/2 in (38.1 mm) Cleats |

| Drive | Hydraulic, Top driven |

| Drive & Idler Roller Type | "Easy Clean" |

| Length | 26 ft. (7.92 m) |

| Width | 30 in. (76.2 cm) |

| Max. Conveyor Discharge Height | 18 ft 3 in (5.56 m) |

| Lift | Electric/Hydraulic |

| Fold | Electric/Hydraulic |

| Oscillation (50°) | Electric/Hydraulic |

| OPERATOR CONTROLS CENTRAL COMMAND CONSOLE | |

| Engine Functions | |

| Battery Disconnect | Rotating key, switch with power off, lock, power on |

| Ignition | Rotating key switch with lock, power on, start, run and power off |

| Throttle | 3-position switch to increase rpm, hold rpm, and decrease rpm |

| Emergency Engine Stop | 2-position switch, pull out to run and push in to stop |

| Tub Grinder Functions | |

| Hammermill | 2-position switch, pull out to engage and push in to disengage 2-position safety switch, push and hold until hammermill begins to spin |

| Conveyor Lift | 3-position switch to raise, hold, & lower |

| Conveyor Oscillation | 3-position switch for right, hold, & left |

| Conveyor Storage | 3-position switch to fold, hold or to unfold |

| Belly & Discharge Conveyor | 2-position switch to engage and disengage |

| Tub Rotation | 3-position switch to operate tub clockwise, stop, & counter-clockwise |

| Tub Speed | Model RCB93 electronic governor stabilizes engine load by adjusting tub rotation speed |

| Tub Tilt | 3-position switch to raise, hold, & lower |

| REAR COMMAND CONSOLE | |

| Conveyor Lift | 3-position switch to raise, hold, & lower |

| Conveyor Oscillation | 3-position switch for right, Hold, & left |

| Conveyor Storage | 3-position switch to fold, hold or to unfold |

| REQUIREMENTS FOR OPERATION TRUCK SPECIFICATIONS | |

| Min. Truck Horsepower | 300 HP (223.7 kw) |

| Min. Rear Axle(s) Capacity | 31,100 lbs (14,106.7 kg) |

| Min. Front Axle Capacity | 9,650 lbs (4,377.17 kg) |

| Recommended Rear Axle Suspension | Air ride with dump valve (to lower loading height) |

| Frame Width | 34” +/- 1/2” |

| Frame Material | Steel |

| Fuel Tanks | Dual tanks are recommended Minimum of 200 gal for truck and grinder combined use, if off-road fuel is allowed for truck use in this application. Minimum of (1) 150 gal and (1) 50 gal tanks if off-road fuel is not for truck use. Minimum of (1) 50 gal min if optional 211 gal truck style tank is selected (see fuel system setup instructions for more information) |

| Fuel System Setup Methods | Method 1 - Tanks should be connected with a minimum of ½ in crossover fuel line with quarter-turn shutoff valves at each tank. Grinder and truck will share fuel source. DO NOT tee off of truck supply lines, this will un-prime the truck fuel system. This setup is recommended only if local laws allow off-road fuel use in this truck in this application. Method 2 - Truck and grinder will each use a fuel tank dedicated to their separate operation. It is recommend that the tanks be connected with a crossover line with shutoff valve so the truck source tank can be used for a grinder reserve tank. Method 3 - Truck is equipped with one tank for the truck engine on driver’s side. An optional 211-gallon tank will be installed on the passenger side. Adequate space will be required under truck cab for the tank |